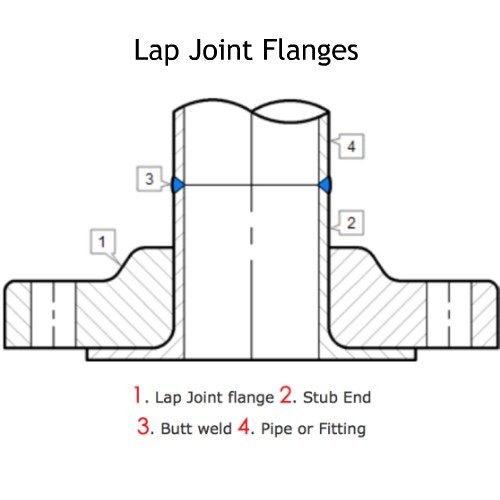

Lap Joint or Loose Flanges Manufacturers & Suppliers

The lap joint flange has a similar shape with slip on flange, and similar dimensions too. However, lap joint flanges are not widely used in high pressure conditions, but it is generally suitable for piping systems where the assembly and disassembly of the pipeline is frequent.

- Lap Joint or Loose Flange Available for Sale in Sizes 1/2" to 60"

- Material Grades: Stainless Steel, Carbon Steel, Alloy Steel, Cupro Nickel (90/10, 70/30, 66/30/2/2), Hastelloy (C-4, C-22, C276, B-2), Nickel (200 / 201), Monel (400 & K500), Inconel (600, 601, 625 & 825), Incolloy (800, 800H), Alloy 20, Duplex Steel, SS 904L, Titanium (1 & 2) Etc.

- Pressure Rating: 150 to 2500 Class, PN 2.5 to PN 100

- Lap Joint or Loose Flange Manufactured in Various Standards & Specifications including ANSI/ASME Flanges, BS Flanges, DIN Flanges, EN 1092-1 Flange, JIS Flange

- Certification as per EN 10204 3.1

- Manufacturing Specification: A182, A240

Metline is a professional manufacturer and exporter of lap joint flanges (loose flanges) with in-house precision machining facilities. We produce lap joint flanges as per ANSI B16.5, DIN Standard and EN1092-1 in size range of 1/2” to 24” NPS. We can also produce and supply lap joint flanges for high pressure and high temperature applications. We produce lap joint flanges in carbon steel, stainless steel, high nickel alloys, duplex/super duplex, copper nickel, titanium and special alloys.

Our manufacturing process for lap joint flanges includes an adequate heat treatment and the examination of chemical and mechanical properties. We have

CNC machines as well as conventional lathe machines for machining and processing various types of lap joint or loose flanges.

Lap joint flanges are generally made from forged bar stock. The raw materials used for manufacturing lap joint flanges include raw round bar of diameter size 20~400mm OD or billets for large size flanges.

Why Choose Metline, as Your Source for Lap Joint or Loose Flanges?

- More Than 3 Decades of Experience in Stock & Supply of Lap Joint or Loose Flanges

- Best Prices For Lap Joint or Loose Flanges Manufactured by Metline and Exported Worldwide

- Exporting Lap Joint or Loose Flanges is Our Specialty

- We Can Handle the Logistics for You - We can offer Exworks, FOB, CFR, CIF Delivery to Any Port

- Documents We Provide Include - Certificate of Origin, Invoice & PL Attested by Chamber of Commerce, Test Certificates as per EN 10204 3.1, Other Testing Reports, as may be Required by Our Customers.

- Complete Traceablility for Lap Joint or Loose Flanges - All Our Products will have Complete Marking on Flanges and/or Packaging, and the Details can be co-related to the Test Certificates.